Installation costs play a crucial role in any project, impacting budgets and timelines. From material choices to labor expenses, various factors influence these costs. In this detailed narrative, we delve into the complexities of installation expenses, offering insights and tips for effective cost management.

As we navigate through the intricate world of installation costs, we uncover the significance of accurate estimations, cost-saving strategies, and comparative analyses that can shape the success of any project.

Factors influencing installation costs

When it comes to installation costs, there are several factors that can influence the final expenses. From material choices to labor costs, each element plays a crucial role in determining the overall cost of a project.

Material Choices

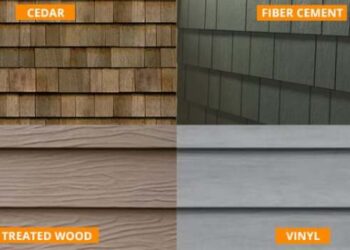

The type of materials used in a project has a significant impact on installation costs. High-quality, premium materials typically come with a higher price tag, increasing the overall expenses. Conversely, opting for more budget-friendly materials can help reduce installation costs without compromising on quality.

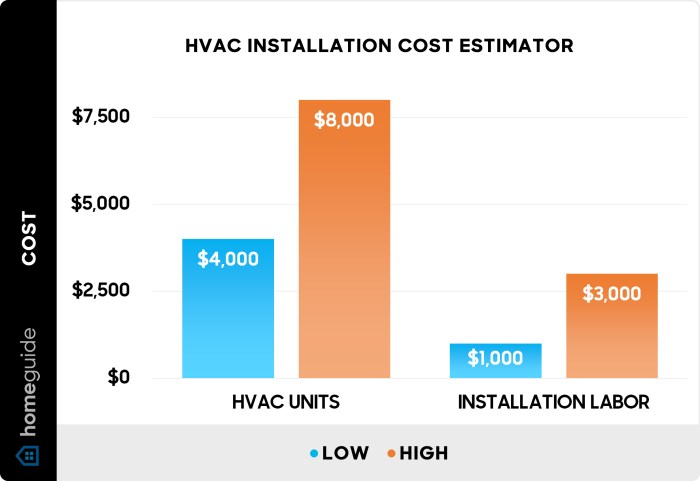

Labor Costs

Labor costs are another key factor that influences installation expenses. Skilled labor is essential for a successful project, but it often comes at a higher price. The expertise and experience of the workers involved can impact the overall cost of installation significantly.

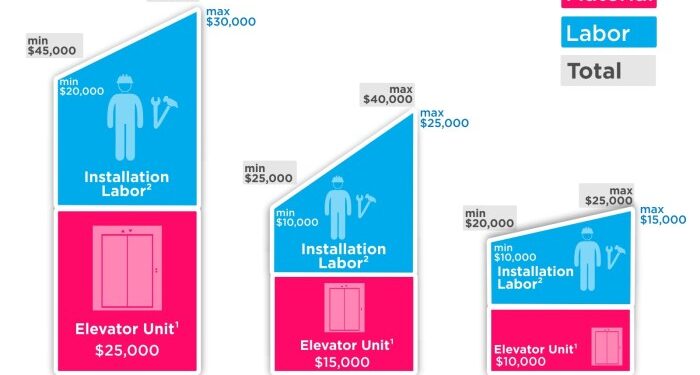

Residential vs. Commercial Projects

Installation costs can vary depending on the type of project, whether it is residential or commercial. Commercial projects often involve larger-scale installations, which can drive up costs compared to residential projects. Additionally, the complexity and requirements of commercial installations can also contribute to higher expenses.

Methods for Estimating Installation Costs

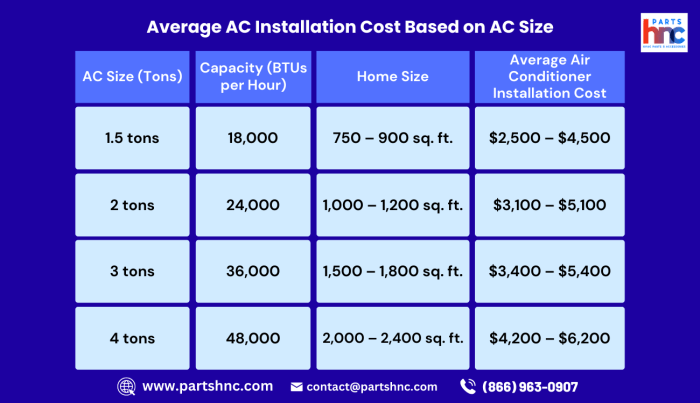

Estimating installation costs accurately is crucial for effective project planning and budget management. Various methods and tools are commonly used to calculate installation expenses, ensuring that projects stay within budget and are completed on time.

Common Approaches to Estimate Installation Expenses

- Bottom-Up Estimation: This method involves breaking down the project into smaller components and estimating the costs of each individual task. These estimates are then aggregated to determine the total installation cost.

- Analogous Estimating: This approach relies on historical data from similar past projects to estimate installation costs for the current project. It is especially useful when detailed information is limited.

- Parametric Estimating: Using statistical relationships between historical data and project parameters, this method calculates installation costs based on specific project characteristics.

Tools and Software for Calculating Installation Costs

- Spreadsheet Software: Programs like Microsoft Excel or Google Sheets can be used to create detailed cost estimates, including labor, materials, and equipment expenses.

- Estimating Software: Tools like ProEst, Clear Estimates, or CostCertified provide specialized features for accurately calculating installation costs and generating professional estimates.

Importance of Accurate Cost Estimates in Project Planning

Accurate cost estimates are essential for project planning as they help stakeholders make informed decisions, allocate resources effectively, and avoid budget overruns. By having a clear understanding of installation costs, project managers can set realistic budgets and timelines, ensuring project success.

Tips for Effectively Estimating Installation Expenses

- Consult with experts: Seek input from experienced professionals in the field to ensure accurate cost estimates.

- Use multiple estimation methods: Combining different approaches can help validate cost estimates and provide a more reliable projection of installation expenses.

- Factor in contingency: Include a contingency fund in the budget to account for unexpected costs or changes during the installation process.

- Regularly review and update estimates: As the project progresses, revisit cost estimates to account for any changes or deviations from the original plan.

Cost-saving strategies during installations

Planning ahead and implementing cost-saving measures during installation projects can significantly reduce expenses and optimize the overall budget. By considering alternative materials or methods and utilizing value engineering principles, installation costs can be minimized effectively.

Benefits of Planning Ahead

- Early project assessment helps identify potential cost-saving opportunities.

- Proper planning reduces the risk of unexpected expenses during the installation process.

- Allowing sufficient time for research and procurement of materials can lead to better deals and discounts.

Alternative Materials and Methods

- Exploring recycled or repurposed materials can offer cost-effective solutions without compromising quality.

- Utilizing prefabricated components can streamline the installation process and reduce labor costs.

- Consideration of energy-efficient options can lead to long-term savings on operational costs.

Value Engineering in Minimizing Costs

- Value engineering involves analyzing the function of components and identifying cost-effective alternatives that provide the same benefits.

- By focusing on value rather than simply cutting costs, value engineering ensures that installations remain efficient and effective.

- Collaboration between designers, engineers, and installers can help optimize the use of resources and reduce unnecessary expenses.

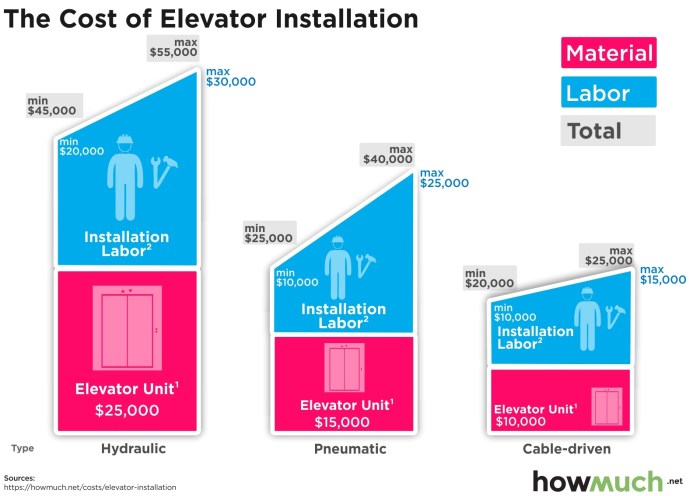

Comparative analysis of installation costs

When comparing installation costs for different types of projects, such as plumbing versus electrical work, it is important to consider the complexity of the task, the materials involved, and the expertise required. Plumbers may charge differently than electricians due to the nature of their work and the specific requirements of each project.

Impact of geographic location on installation expenses

The geographic location can significantly impact installation expenses. In areas where skilled labor is scarce, installation costs may be higher due to increased demand. Additionally, the availability and cost of materials can vary depending on the region, affecting overall project costs.

Trade-offs between upfront installation costs and long-term savings

- Investing in high-quality materials and professional installation services upfront may result in higher initial costs but can lead to long-term savings by reducing the need for repairs or replacements.

- On the other hand, opting for cheaper materials or inexperienced labor to cut installation costs initially may result in higher maintenance expenses in the future, negating any initial savings.

Case studies on successful cost management in installation projects

One successful cost management strategy in installation projects is thorough planning and budgeting. By accurately estimating costs, identifying potential risks, and exploring cost-saving options, project managers can ensure that installation expenses stay within budget.

Conclusion

In conclusion, understanding installation costs is key to successful project planning. By considering the factors, estimation methods, and cost-saving strategies discussed, individuals and businesses can make informed decisions that lead to efficient and budget-friendly installations.

Essential FAQs

What factors can impact installation costs?

Factors such as material choices, labor expenses, project type (residential/commercial), and geographic location can all influence installation costs.

How important are accurate cost estimates in project planning?

Accurate cost estimates are crucial for effective project planning as they help in budgeting, resource allocation, and overall project success.

What are some cost-saving strategies during installations?

Planning ahead, using alternative materials/methods, and implementing value engineering are effective cost-saving measures during installation projects.

Why is a comparative analysis of installation costs important?

Comparative analysis helps in understanding cost variations for different projects, locations, and types, enabling informed decision-making for cost management.

How do trade-offs between upfront installation costs and long-term savings impact projects?

Considering trade-offs helps in balancing immediate expenses with long-term benefits, ensuring cost-effectiveness and sustainability in projects.